The delamination split is a worry and yes I have seen it. I think it goes back to when T/L was caught in a strong SW blast at a Regatta Sail Past following an AWBF.

The delamination split is a worry and yes I have seen it. I think it goes back to when T/L was caught in a strong SW blast at a Regatta Sail Past following an AWBF.

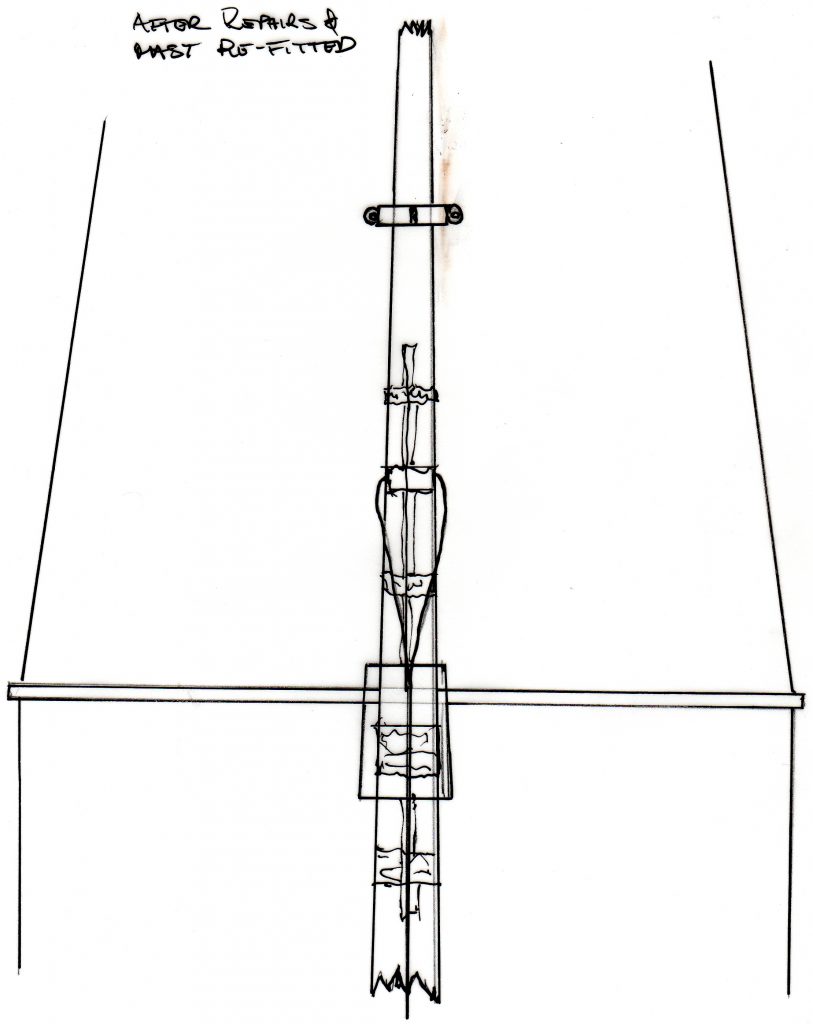

We broke the boom jaws and spreaders which possibly sprung the mast. The John Leather “Gaff Rig Handbook” mentions “… suddenly fails in a hard blow it may also damage or spring the mast”. However, we did not see the delamination but it has possibly opened up with time. We replaced the jaws and fixed the spreaders without taking the mast out hence the mess around the spreaders cheeks but that is cosmetic and easy fixed. We just need to clean up the Sika on the Cheeks and mast, then mask it up and reapply Sika to a neat finish. I am fairly confident the spreaders are firmly fixed to the mast but please check this?

We do however, need a bit more to do with the delamination and reinforcing that area without anything metal that aids rot and water ingress to the mast. I have re-though my comment about using dump pins and also I heard some one suggest a metal gusset. The one issue with masts is to make sure all potential water ingress is minimised to prevent weak spots and dry rot in the mast. S.S. Gussets or Bands will hold water underneath them and cause dry rot over time.

So I suggest the solution is once the mast is back to bare wood;

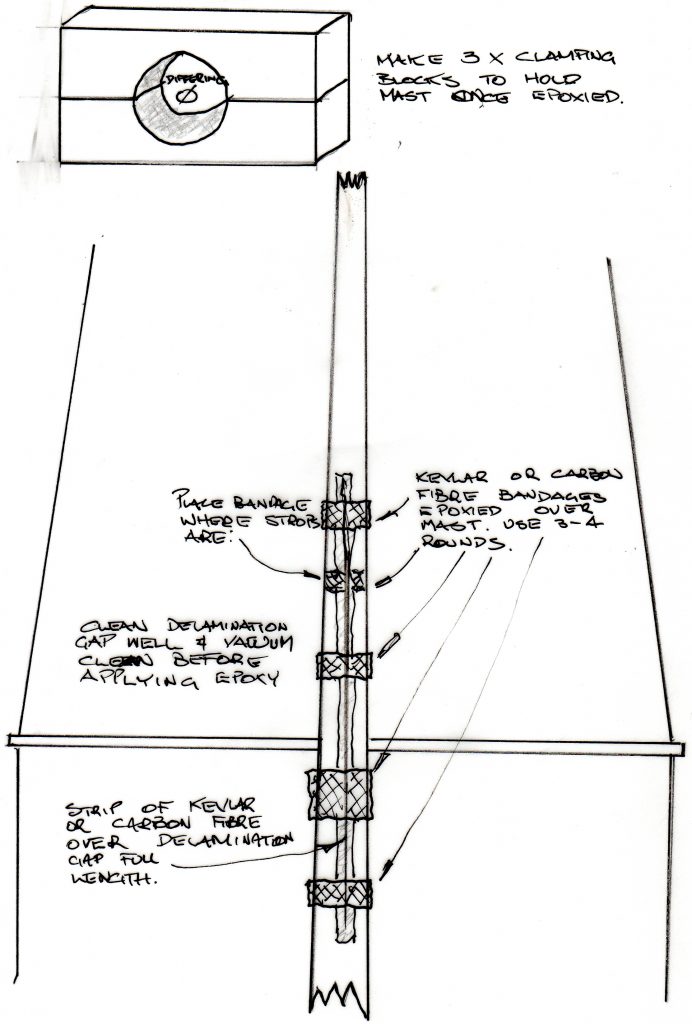

- Clean out and vacuum the delamination crack.

- Make at least three clamping blocks as per the attached drawings.

- Purchase some 75mm Kevlar or Carbon Fibre tape, enough for at least three rounds per bandage as per the drawings. Making sure there is one under each strop placement will also double to prevent chafing as well as holding the mast delamination together.

- Once all cleaned up and dried apply some epoxy to the delamination gap then apply the clamp blocks. Where the clamp block go over the delamination gap apply some Vaseline to the blocks. This will work as a release agent.

- Then where the bandages will go apply a thin coat of epoxy and then wrap the bandage for at least 3 rounds. The epoxy should hold it in place. Apply a thin coat of epoxy over the bandage, do not over do it with the epoxy.

- Then layer the strip over the delamination gap by applying a thin coat of epoxy over it first then lay the strip into the epoxy. Once the strip has adhered give it another light coat of epoxy.

- Each day for 3 days rub the bandages and strip back lightly, clean it with acetone. Then apply another thin coat of epoxy.

- Do not oil the mast until this work is complete.

This remedy should allow the mast to serve us for a good few years.

11 Responses